PCB Testing

We use a thorough PCB testing process to ensure your products have been fully tested and inspected before shipping.

Enquire Here

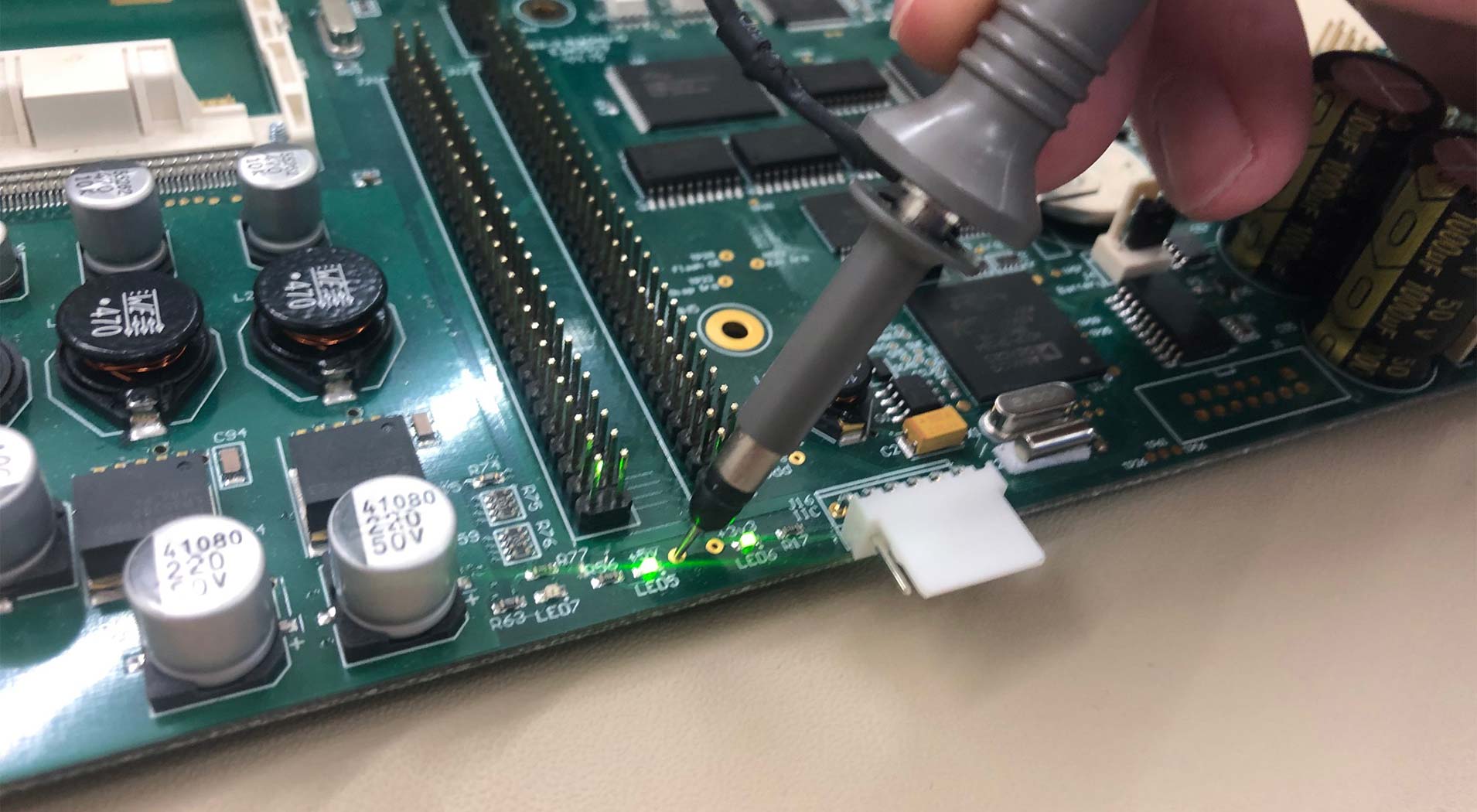

PCB Board

Testing

We design and manufacture all of the required PCB board testing equipment in our UK based factory. Meaning you can be reassured that we thoroughly test and inspect every printed circuit board and piece of equipment before it leaves our workshop.

PCB testing is a vital step of the manufacturing process and not something we take lightly. Some applications require us to build job specific, fully automated custom test rigs to ensure every aspect of the board is tested efficiently. Having fully tested PCBs delivered to you means one less thing for you to do, allowing you to get up and running as quickly as possible.

Where possible all of our PCBs are ultrasonically cleaned. This ensures flux residue and other contaminants are removed. Should your project require them to be cleaned without ultrasonics please let us know and we will arrange this for you.

Our available test and finishing equipment includes :-

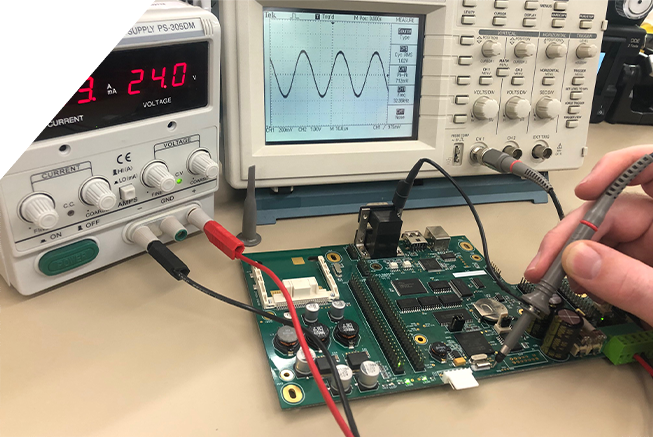

- Tektronix oscilloscopes

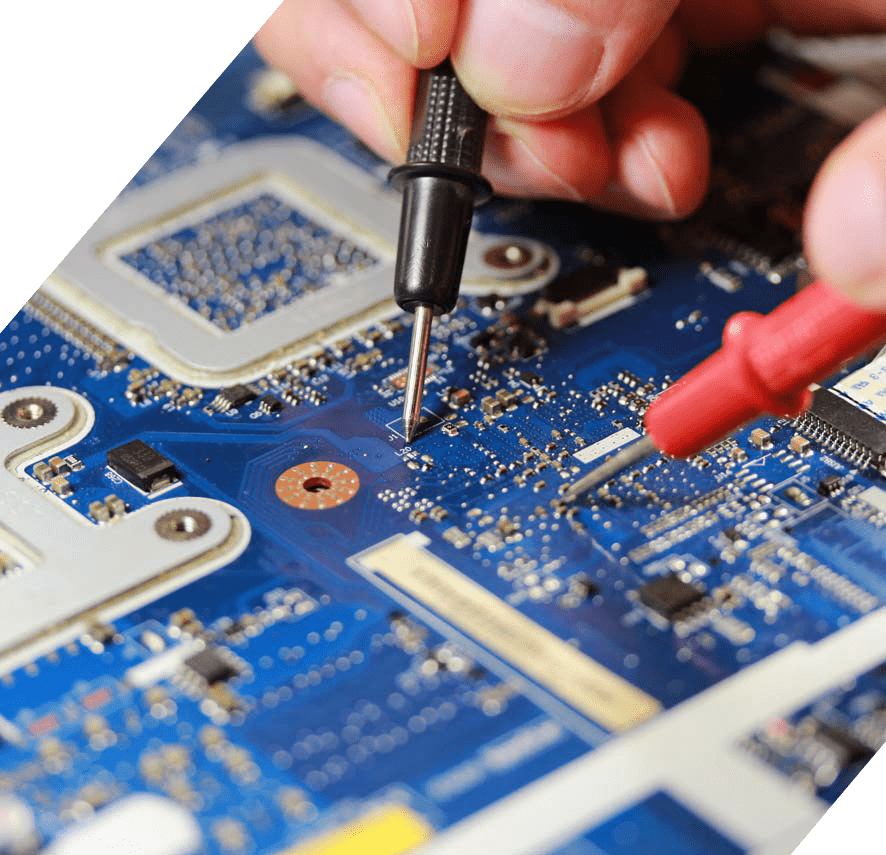

- Digital / Analogue Multimeters

- Frequency Counters

- Thurlby Thandar Pulse Generator

- Signal generator

- Yestech (Yield Enhancement Solutions) Automated Optical Inspection (AOI)

- Lynx dynoscope

- FKN Systek depanelizer

- JBC rework station

- Pace rework stations

- Various semiconductor programmers including (Microchip ICD2, Pickit 3, WinLV Micromaster, Zilog, ARM, PIC, Serial)

- Bench DC PSU's

- Variac transformer

- Large capacity air compressor

- Air flow gauges

- Air pressure gauges

- 4 stage ultrasonic cleaner and dryer

PCB Testing & Finishing

Our PCB testing services do not stop as soon as you receive your products, we offer a range of after care services to ensure your PCBs continue to work as they should, including;

- Warranty and Out of Warranty repairs

- Recalibration

- Software updates

- Product upgrades and modifications

We offer a range of options when it comes to finishing the PCBs, all of our boards can be finished using conformal coating (either dipping or spray) to protect them, we also offer potting compounds and encapsulation should you require them and serial numbers are used for traceability where appropriate.

After your PCBs are finished we can assemble them into their final product meaning you can be assured that your product will work exactly as expected as soon as you receive it.

To find out more information on our testing process or to speak to one of our experts please fill out the short form below.

Enquire Here